Machining manufacturing Adelaide

Precision engineering for small to medium parts, from concept to finish

Hawk Tooling delivers expert machining manufacturing services in Adelaide, including CNC machining, laser welding, laser etching, 3D prototyping, CAD design and turnkey tooling solutions for local industries.

Specialist machining and manufacturing services in Adelaide

Hawk Tooling offers a full range of precision manufacturing services to support product development, new or pre-designed parts, part/tool Mods and repairs, and customised production. Our capabilities cover everything from one-off component to complete component/tooling design and production-ready for high volume output.

Laser welding Adelaide

Repair worn tooling, restore cavity edges, and join delicate or complex parts with high-precision fibre optic laser welding. It’s ideal for component repair and tooling rework with minimal heat distortion.

CNC machining Adelaide

From prototypes to production runs, we machine complex parts in aluminium, stainless steel, tool steels, plastics, copper, and more. Suitable for mining, electronics, and general manufacturing.

Laser etching and engraving Adelaide

Mark logos, serial numbers, part IDs, or safety information with sharp, permanent results. Our fibre laser system delivers deep engraving and fine detail on a range of metallic items.

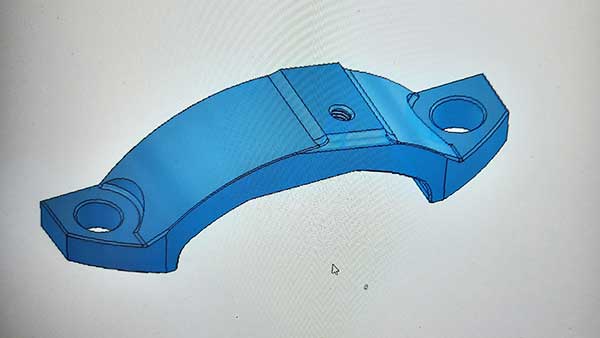

3D prototyping & CAD design Adelaide

We turn ideas and rough sketches into production-ready 3D models. Our CAD and prototyping services streamline manufacturing and reduce turnaround times for complex mechanical parts.

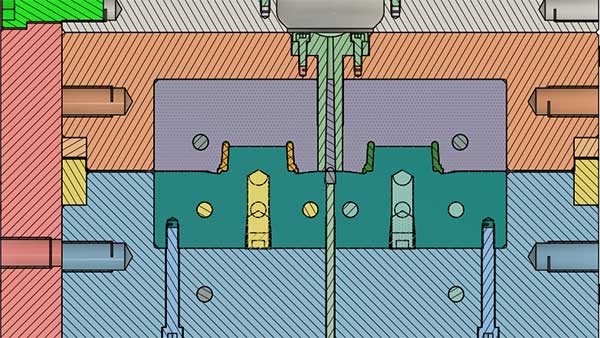

Tooling design and manufacturing Adelaide

We build and modify small to medium injection molds and press tools up to 1000kg. We offer complete tooling solutions, from open-and-shut molds to multi-slide and hot runner systems.

Trusted by industries across Adelaide and South Australia

Our work supports a wide range of industries where precision, quality, and flexibility are essential. The requirements may be producing custom components, repairing critical tooling, or helping with design and prototyping. Hawk Tooling is the go-to partner for small to medium manufacturing challenges.

Mining and resources

We manufacture and repair high-performance parts used in harsh environments, helping mining operations stay productive and reduce downtime.

Electronics and technology

From custom PCB housings to detailed assemblies, our CNC and laser services meet the electronics sector’s tight tolerances and technical demands.

Injection molding and plastic products

We work closely with manufacturers or mold shops to design, modify, and repair tooling for plastic part production, supporting everything from consumer products to industrial components.

General manufacturing and engineering

Our versatile capabilities deliver efficient and cost-effective results for businesses needing precision parts, prototyping or low-to-mid-volume production.

Medical, transport, and niche industries

Our services extend to specialised components and tooling for medical devices, transport infrastructure, and even unique sectors like aquaculture and office systems.

About Hawk Tooling

With over 35 years of hands-on industry experience, Hawk Tooling combines deep technical knowledge with a practical, solution-focused approach to manufacturing.

Led by experienced toolmaker Jarrod Clark, the business was founded to support Australia’s manufacturing industry with services beyond basic machining, delivering design, prototyping, tooling and production under one roof.

We specialise in designing, machining, and repairing components and assemblies across a wide range of materials, including aluminium, steel, plastics, copper and more.

We’re known for completing complex jobs correctly, communicating clearly, and meeting tight deadlines without compromising quality. This is why engineers, production teams and business owners across Adelaide choose Hawk Tooling.

Our approach to manufacturing

Every project is different, and we adapt to meet the scope, whether a quick turnaround for a single repair or a complete concept-to-production workflow.

We work with everything from rough sketches to fully developed CAD files, supporting customers through design, prototyping, machining, and quality assurance. Our process is hands-on, collaborative, and focused on delivering reliable outcomes that perform in the real world.

Equipment and technology built for precision

Our workshop has advanced machinery to handle complex and detailed manufacturing tasks. From CNC machining and laser welding to CAD design and metrology, every job is backed by reliable tools and technology that ensure consistent, high-quality results. Our in-house capability allows us to move quickly from design to delivery, reducing lead times and keeping quality in check at every step.

Hawk Tooling in-house core capabilities

CNC machining and turning

Our Puma 250 CNC lathe and Syil X7 4-axis vertical milling machine allow us to machine complex parts with high precision and repeatability.

Laser welding and engraving

We use a 2KW fibre optic 4-axis CNC laser system for precision welding of delicate or complex components, and a 50W fibre laser engraving system for detailed marking and ID work.

EDM and manual machining

Our Chmer EDM machine, manual mills, and lathes allow for specialist machining and one-off operations that require fine control.

CAD design and modelling

Using Autodesk Fusion 360 and AutoCAD, we support complete CAD/CAM workflows for prototyping, modelling, and production-ready design.

Surface finishing and coatings

We offer fine bead blasting, surface grinding and highly polished surfaces, along with MIL-spec Alodine chemical conversion coating systems for corrosion resistance and surface treatment.

Metrology and inspection

Quality control is supported by Mitutoyo instruments, granite surface tables, microscopes, and gauges in a climate-controlled environment to ensure dimensional accuracy.

Production tooling and support equipment

Our Schaublin turret lathe and small sheet metal panbrake support small part production, helping keep costs down instead of paying for complexed CNC equipment rates.

Why engineers and manufacturers choose Hawk Tooling

We offer more than a typical small-to-medium machine shop. With in-house design, CAD modelling, and advanced tooling capabilities, we support projects from concept to production with the precision and flexibility of modern manufacturing demands.

Here’s what sets Hawk Tooling apart

Advanced problem-solving

We take on complex and specialised work that others avoid.

Integrated services

Design, prototyping, machining, and tooling under one roof.

High-precision capability

Flexible approach

We adapt to your project needs, from urgent repairs to full production.

Straightforward communication

Work directly with the decision-maker and get clear, honest updates.

Reliable turnaround

Fast response times without compromising quality.

Supporting Adelaide’s major industrial areas

Based in Lonsdale, Hawk Tooling works with clients across Adelaide’s key manufacturing and industrial hubs, delivering reliable service and high-quality results no matter where you’re based.

We regularly support businesses in Lonsdale, Edwardstown, Plympton, and Elizabeth South, and also work with clients across high-density industrial zones such as Port Adelaide, Salisbury, Wingfield, Pooraka, Beverly, Mawson Lakes, Mile End, Gepps Cross, Richmond and Tonsley.

Our services extend throughout metropolitan Adelaide and regional South Australia, and we also provide specialist manufacturing support to clients across Australia when technical capabilities or expertise are required.

If you’re looking for a trusted machining partner nearby or need national support for complex projects, Hawk Tooling is ready to help.

What our customers say

![]() 5-star Google reviews

5-star Google reviews

We often hear the same things from the engineers, production teams, and business owners we work with that Hawk Tooling delivers where others fall short. Our focus on high-quality work, clear communication and doing things right the first time is reflected in the feedback we receive.

Gold star customer service! Good response times!

The owner is a really nice guy. Would recommend.

Went here for some laser welding assistance. Guy was fantastic and very efficient.

Contact Hawk Tooling

Your small to medium-part precision manufacturing partner

If you’re looking for a reliable, experienced machine shop that delivers precision and flexibility, Hawk Tooling is here to help.

We specialise in high-quality machining manufacturing for small to medium parts, including CNC machining, laser welding, tooling repairs, 3D modelling and prototyping. We support everything from urgent component repairs to complete production and tooling projects.

Reach out to discuss your requirements, ask questions, or request a quote. You’ll deal directly with the owner and engineer behind the business to provide practical advice and fast, honest communication.