3D prototyping & CAD design Adelaide

Accurate CAD models and prototypes for tooling, components and manufacturing

CAD design and prototyping services

Hawk Tooling’s CAD design and 3D prototyping services are used by engineers, toolmakers and manufacturers who need accurate, production-ready models that align with daily performance and manufacturability.

Our service is ideal for businesses needing speed, technical accuracy, and direct communication with someone who understands both design and production. If you’re preparing for machining, testing a concept, or refining an existing part we are here to help bridge the gap between idea and reality.

We support a wide range of design needs

- Developing tooling and mechanical components for CNC machining or fabrication

- Converting hand sketches or rough ideas into detailed 3D CAD files

- Creating prototypes to test fit, form, and function before committing to production

- Modelling assemblies or mating parts that must align precisely in use

- Supporting R&D and product development for one-off or short-run applications

Our design and modelling capabilities

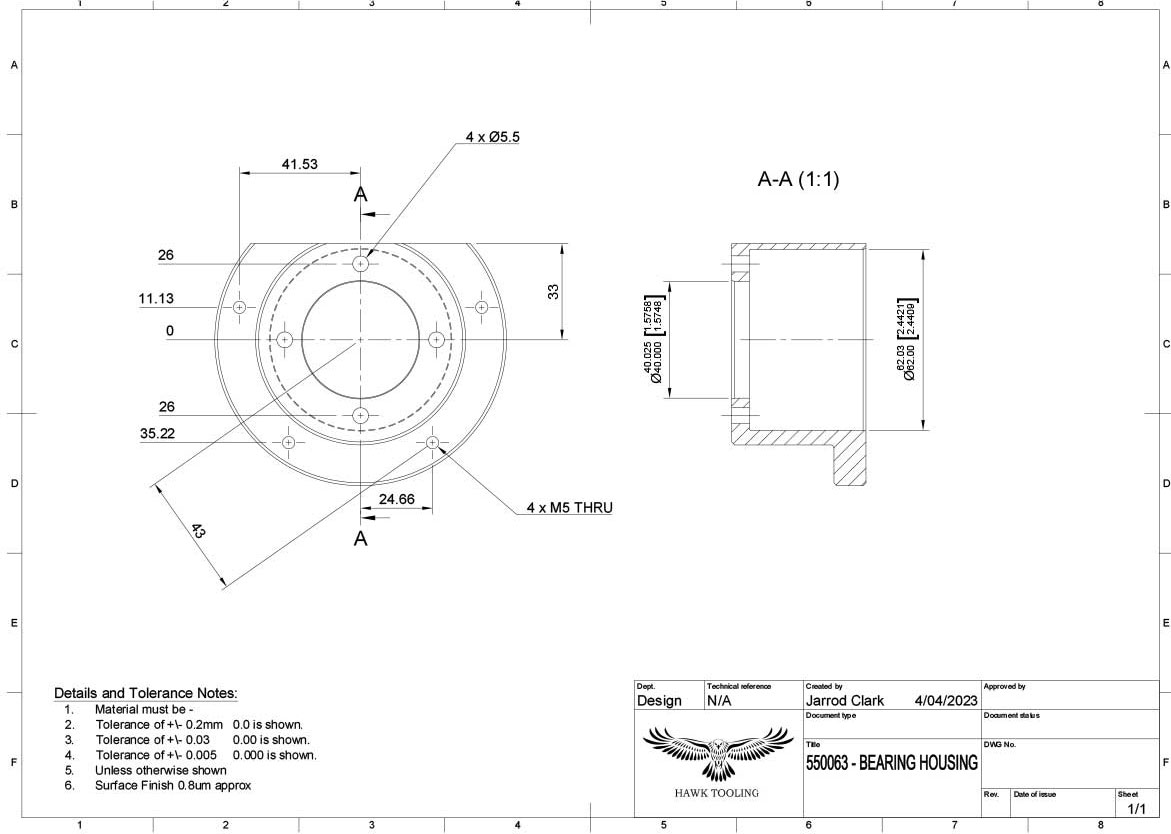

We use Autodesk Fusion 360 and AutoCAD to produce high-accuracy 3D models and mechanical designs suited for manufacturing, assembly and performance under load. With decades of experience in tooling and part fabrication, we know what makes a design functional and buildable.

We’re not just drawing parts. We’re designing with materials, machines, functionality and tolerances in mind. That makes our CAD work so valuable for small to medium manufacturers.

Our capabilities

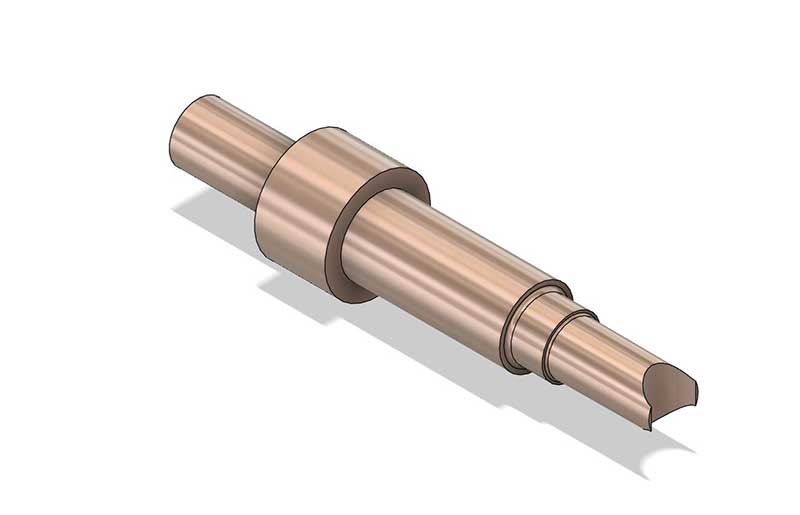

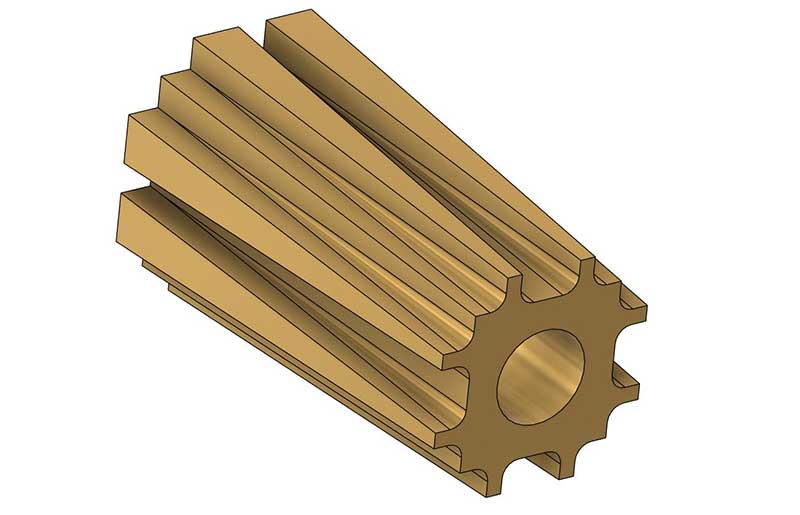

- Complete 3D CAD modelling for components, tooling and assemblies

- Production-ready drawings with dimensional callouts and tolerances

- Modelling for tight-fitting, load-bearing or moving parts

- Design for manufacturability (DFM) insights to reduce machining time and cost

- Exporting files compatible with CNC machining, laser welding and prototyping workflows

- Customer approval of models before manufacturing begins

Projects and components we typically design

Our CAD design and prototyping services are used across a wide range of industries to create functional, accurate, and ready-to-manufacture components. You may require a single part or an assembly; we focus on precision, performance and ease of production.

Every design is created with production in mind, so once it’s approved, it can be machined, welded or assembled without unnecessary delays or rework.

Our 3D prototyping & CAD design projects

- Injection mold components and core inserts

- Press tools, dies, and custom tooling elements

- Machined housings, brackets and structural supports

- Fixtures, jigs, and work holding devices

- Interfacing parts for mechanical assemblies

- Prototype parts for testing and product development

- One-off components for engineers, tradespeople and inventors

From idea to model how our CAD design process works

Our process is designed to take your idea, no matter how developed and turn it into a clear, accurate model that’s ready for production. You may start with a sketch, an existing part, or just an idea in mind; whatever stage you are in, we’ll guide you through the development.

Step 1

Share your idea or requirement

You can provide a hand sketch or reference part or detailed needs. We’ll ask the right questions to understand the function and environment of the part.

Step 2

CAD modelling and design

Using Autodesk Fusion 360 or AutoCAD, we create a 3D model that reflects your component or assembly’s functional and manufacturing needs.

Step 3

Review and feedback

We will share the model with you for review. You can suggest refinements or confirm approval before moving forward.

Step 4

Finalise and prepare for production

Once approved, we prepare the model with appropriate tolerances and details. The file is then ready for CNC machining, laser welding, or other manufacturing processes.

Step 5

Prototype or move to manufacturing

If needed, we can produce a one-off prototype for fit and function testing before full production begins ensuring everything works as intended.

We integrate design with our manufacturing services

One of the most significant advantages of working with Hawk Tooling is that your CAD design doesn’t just stay on a screen; it moves directly into production under the same roof.

Because we handle CNC machining, laser welding, and tooling in-house, we ensure a smooth transition from model to finished part without delays or miscommunication between separate providers.

Benefits of our integrated approach

- Faster turnaround from approved design to the final part

- Fewer revisions and rework due to clear design intent

- Direct alignment between designer and machinist

- Reduced risk of manufacturing errors or oversights

- Better cost control and project visibility from start to finish

CAD design and prototyping for Adelaide industries

Our CAD design and 3D prototyping services support a wide range of industries across Adelaide, from manufacturing and tooling to electronics, mining and product development.

From our workshop in Lonsdale, we serve clients in Lonsdale, Edwardstown, Plympton, and Elizabeth South and work with clients across high-density industrial zones such as Port Adelaide, Salisbury, Wingfield, Pooraka, Beverly, Mawson Lakes, Mile End, Gepps Cross, Richmond and Tonsley. We also support regional South Australian businesses that need a reliable support with fast, accurate design and modelling.

If you’re developing a new product, refining an existing component, or planning a tooling upgrade, we provide the design expertise to move your project forward confidently.

Why choose Hawk Tooling for CAD design in Adelaide

Hawk Tooling combines design expertise and hands-on manufacturing knowledge. That means we model parts that work, fit and can be made efficiently.

With decades of hands-on experience in tooling, machining and component design, we offer more than just CAD software skills. We understand how parts perform, how they’re made and how to make the transition from concept to production smooth and cost-effective.

Why engineers and manufacturers work with us

Over 35 years of experience in design and manufacturing

CAD models optimised for machining, tooling and assembly

Direct communication with the designer and engineer doing the work

In-house integration with CNC machining and laser welding services

Fast turnaround and local support across all Adelaide industrial zones

Reliable outcomes; done right the first time

Frequently asked questions of our CAD design and 3D prototyping services

display none

Can you work from a hand-drawn sketch or idea?

Do I need to know CAD software to work with you?

What types of parts do you typically design?

Can I use the CAD files with another manufacturer?

Do you also create prototypes of the designs you model?

Can you help improve an existing design?

How long does it take to complete a CAD design?

Request a CAD design or prototyping quote

Do you need a 3D model, engineering drawing, or prototype for your next project? Hawk Tooling provides expert CAD design and prototyping services, bridging the concept and production gap.

We work with engineers, manufacturers, and product developers across Adelaide to turn ideas into accurate, ready-to-manufacture components with practical advice and fast turnaround.

Contact us today

- Discuss your project or part requirements

- Get expert input on manufacturability and design

- Request a fast, competitive quote for CAD design or prototyping