CNC machining Adelaide

High-accuracy CNC milling and turning for components, tooling and assemblies

We provide CNC machining in Adelaide for small to medium parts across all materials supporting prototypes, production runs, and complex tooling with consistent, high-precision results.

CNC machining services

Hawk Tooling’s CNC machining services are trusted by manufacturers, engineers and production teams who need accurate, repeatable results across a wide range of part types and applications.

We support projects from first-off prototypes through to full production runs, offering tight tolerances and reliable lead times across industries such as mining, electronics, medical, general manufacturing, and various tooling.

Our CNC machining services and applications

- Machining custom housings, brackets, and various precision components

- Producing jigs, fixtures, and tooling parts for production environments

- Delivering high-precision mechanical parts for assemblies

- Creating short-run parts for R&D, testing, or pre-production

- Supporting in-house or external repairs by remaking or modifying parts

Our CNC machining capabilities

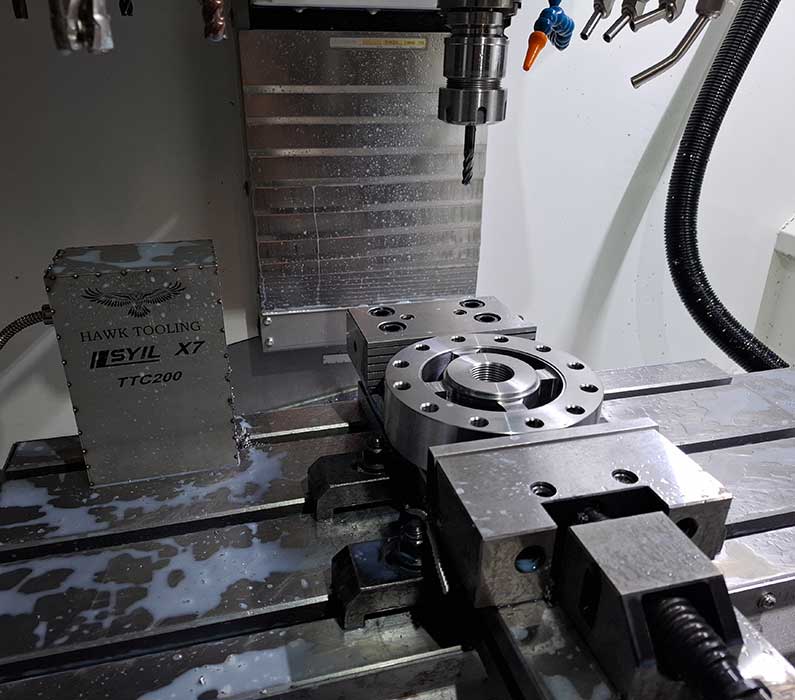

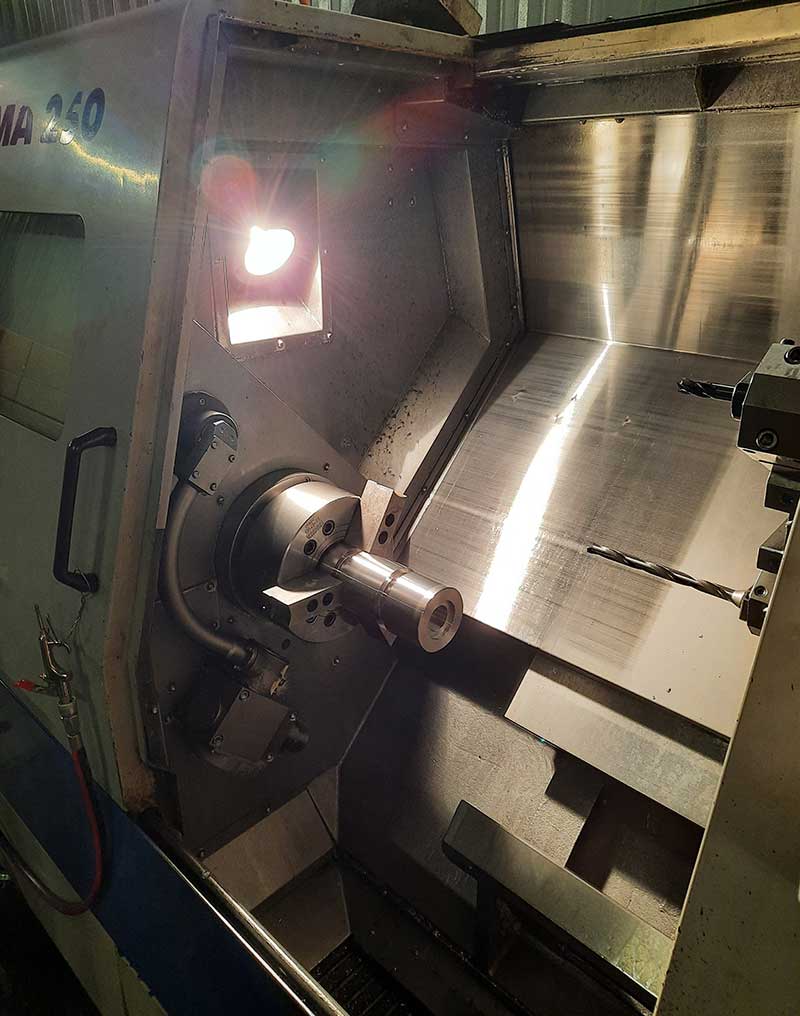

Hawk Tooling uses advanced CNC equipment and a hands-on engineering approach to deliver consistent results across one-off jobs, batch runs and production-scale machining. Our workshop is designed for flexibility, allowing us to switch quickly between different materials, part sizes, and project scopes without compromising quality.

Our in-house CNC capabilities

- 4-axis vertical CNC milling for complex geometries, angled surfaces, and precision slotting.

- CNC turning for round parts, shafts, threads, and concentric features

- High-accuracy repeatability ideal for production runs or mating components

- Tight tolerance machining suitable for mechanical assemblies and fine-fit applications

- Complex part geometry able to produce contours, pockets, undercuts and tapers

- Secondary operations and preparation including bead blasting, surface grinding, deburring, polishing and coatings.

Components and products we commonly machine

Our CNC machining services are used to producing a wide variety of components ranging from high-tolerance mechanical parts to functional assemblies and tooling elements. We work with businesses across Adelaide’s industrial sectors to deliver parts that meet both technical, quality and production demands.

Typical parts and products we machine

- Custom enclosures and housings for electronic assemblies

- Precision brackets, plates and mounting blocks

- Mining and industrial machine components

- Press tool elements, mold inserts and replacement tooling

- Fixtures, jigs, and setup components for production lines

- Threaded parts, pins, shafts and bushings

- Prototype parts for design validation and testing

From prototype to production, our 5-step CNC machining process

Our process supports everything from one-off prototypes to repeat production runs, focusing on precision, efficiency, and clear communication.

Step 1

Share your design or idea

We can work from CAD files, engineering drawings, or even hand-marked sketches. If needed, we’ll offer input to improve manufacturability.

Step 2

Prototype or first-off sample

We produce a sample or prototype so you can check dimensions, fit, and function before committing to production.

Step 3

Review and adjust

Based on feedback, we make any required changes to ensure the part meets your technical and performance requirements.

Step 4

Production machining

Once approved, we machine the whole batch whether it’s 10 parts or several hundred with consistent accuracy and surface finish.

Step 5

Inspection and delivery

All parts are checked using our metrology tools before dispatch. We deliver on time and ready for use in your production, assembly or testing workflow.

Materials we machine

We work with a wide range of engineering materials to meet the needs of different industries and applications. It may be that the job calls for lightweight aluminium, corrosion-resistant stainless steel, or tough tool steels; our CNC machines are set up to deliver accurate results across all grades.

We’re also experienced in machining engineering plastics like acetal and nylon and softer metals such as copper and brass. This versatility allows us to support projects ranging from electrical housings to heavy-duty industrial parts, all with the same precision and quality control.

If you’re unsure about material compatibility or performance, we’re happy to provide advice based on 35+ years of hands-on experience in machining and component design.

Metrology and quality assurance

Every part we produce undergoes a controlled inspection process to meet the required specifications. Accuracy isn’t just a claim; it’s something we measure.

In a climate-controlled environment, we use high-precision Mitutoyo instruments, granite surface tables, microscopes and gauges to verify critical dimensions, tolerances, and surface finishes. If it’s a one-off part or a whole production batch, it does not matter; we inspect it throughout the machining process and again before final delivery.

This level of quality assurance gives our customers confidence that parts will fit, perform and last as intended without costly delays or rework.

CNC machining services for Adelaide and beyond

Hawk Tooling provides CNC machining services to manufacturers, engineers, and production teams and we regularly support businesses in Lonsdale, Edwardstown, Plympton, and Elizabeth South, and also work with clients across high-density industrial zones such as Port Adelaide, Salisbury, Wingfield, Pooraka, Beverly, Mawson Lakes, Mile End, Gepps Cross, Richmond and Tonsley.

Our location in Lonsdale in Adelaide’s south gives us fast access to metro and regional businesses, and we also support national clients who need specialist machining for small to medium parts.

We’re known for being responsive, practical, and easy to work with providing high-quality machining without the delays or inflexibility that often come with larger operations.

Why choose Hawk Tooling for CNC machining in Adelaide

With over three decades of hands-on experience, Hawk Tooling has become a trusted CNC machining partner for businesses that value precision, flexibility, and clear communication.

We understand the pressure of tight deadlines, strict tolerances and the need for reliable supply and we deliver consistently, without fuss.

What sets us apart

35+ years of industry experience in tooling, machining, and component manufacturing

Advanced 4-axis CNC milling and turning for complex part geometries

Flexible support across prototyping, short runs, and full production

Fast turnaround and honest quoting from an engineer who understands your job

In-house quality control using metrology-grade equipment in a controlled environment

Broad material capability to suit industries from defence/aerospace to agricultural and general engineering

Frequently asked questions about our CNC machining services

display none

What types of materials can your machine?

We regularly machine aluminium, stainless steel, tool steels, mild steel, copper, brass and a range of engineering plastics like acetal and nylon. If you’re unsure whether your material is compatible, we can assess the product and recommend something suitable.

Do you handle both prototyping and production runs?

Yes. We support one-off prototypes, short runs, and ongoing production batches. Whether you’re testing a concept or need a consistent supply for assembly, we adapt our setup to suit the scope and schedule of your project.

What part sizes can your machine?

Our equipment is suited to small to medium-sized components. Most jobs fall within a range of up to 600mm in size, depending on the geometry and setup. Contact us to discuss your specific requirements.

Can you help improve or adjust my design for machining?

Yes. With over 35 years of experience, we can provide input on manufacturability, tolerances, and material selection to help ensure your part is optimised for cost-effective, accurate machining.

What tolerances can you hold?

We work to tight tolerances suited for precision assemblies and mating components. Standard tolerance is usually ±0.05mm, but we can achieve tighter specifications depending on material, function and geometry.

Do I need to provide a CAD file?

A CAD file is ideal but we can work from technical drawings or a physical sample. We can support you with CAD modelling and prototyping if you’re still in the design stage.

How do you ensure quality before delivery?

All parts go through detailed inspection using various metrology equipment, granite tables, and calibrated gauges. We check parts for dimensional accuracy, surface finish, and consistency before delivery, whether a single item or a whole batch.

Get a CNC machining quote or speak with an expert

Do you need a precise, reliable machining partner for your next project? Hawk Tooling delivers CNC machined parts that meet tight tolerances, strict timelines and real-world performance expectations.

If you’re developing a prototype, need production parts, or want to restore a critical component, we’re ready to help with honest advice and direct communication from the person doing the job.

Contact us today

- Discuss your part or project requirements

- Get advice on materials, tolerances, or manufacturability

- Request a fast, competitive quote