Laser etching and engraving Adelaide

High-precision laser engraving for part IDs, logos, tags and more

Laser etching and engraving Adelaide services

Hawk Tooling’s laser etching and engraving services are trusted by manufacturers, engineers, and technicians who need accurate, permanent markings on metal parts and components. These markings are essential for part identification, traceability, branding, safety compliance, and workflow efficiency across various industries.

Laser etching and engraving are ideal for applications where ink, stickers, or stamping would wear off or compromise the appearance or performance of the part. We help customers meet industry requirements, reduce confusion on the shop floor, and present a professional finish on everything from tools and tags to production components.

Laser etching and engraving

- Serial numbers, barcodes, and batch tracking codes

- Logos, brand names, and customer-supplied artwork

- Material specifications, warning labels, and safety information

- Asset tags, tool IDs, and custom inventory numbers

- Engineering or assembly data for internal use

Laser etching vs engraving, what’s the difference?

While often used interchangeably, laser etching and laser engraving are technically different processes, each suited to specific applications depending on material type, surface finish, and durability requirements.

Laser etching uses lower power and marks only the surface layer. It’s faster and ideal for light, high-contrast markings such as part numbers, logos, or QR codes where depth isn’t required.

Laser engraving removes more material to create deeper, more permanent marks. It’s the better option for harsh environments where markings need to resist abrasion, chemicals or constant handling.

Hawk Tooling uses a high-powered fibre-optic laser system capable of both etching and engraving. If your part needs a light surface mark or a deep, industrial-grade identification, we’ll advise you on the best approach for the desired result.

Materials we can mark and engrave

We specialise in laser etching and engraving on metal surfaces, using a fibre optic laser system designed for precision, clarity, and durability. Our setup is ideal for a wide range of engineering and industrial materials commonly used across manufacturing and tooling.

We regularly mark

- Stainless steel

- Tool steel

- Aluminium (including anodised surfaces)

- Copper and brass

- Other coated or finished metal surfaces

Metal only marking

We focus on metal-only marking with a work area of approximately 300mm x 300mm. Our service is ideal for small to medium-sized components, plates, housings, and tags.

What we can mark with laser engraving

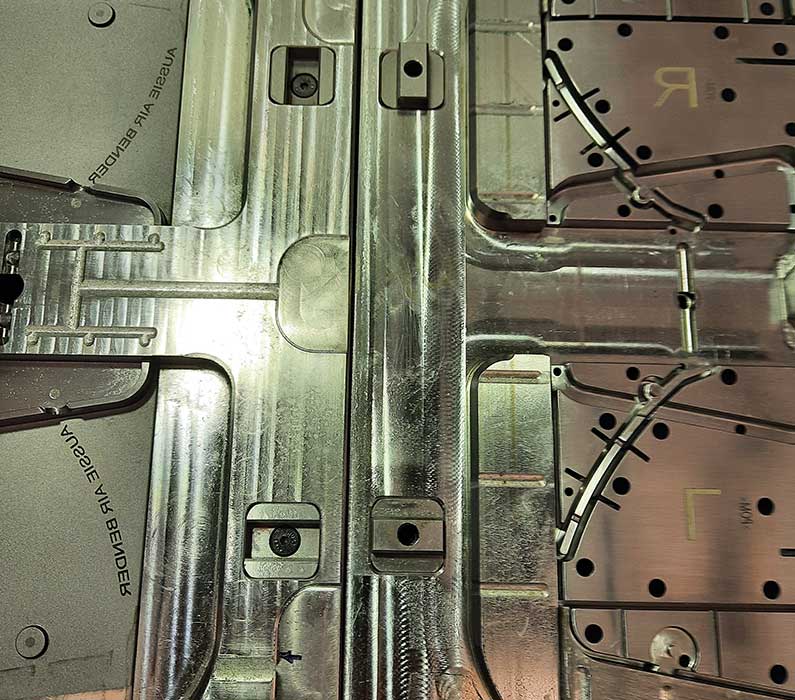

Our laser engraving service marks various components, tools and production-related items. If you need clear branding, traceability or functional data on a part, we provide accurate and permanent results that meet industrial standards.

We work with manufacturers, engineers, and technicians who need consistent marking that holds up under daily use. Each mark is sharp, permanent, and resistant to wear, ideal for industrial environments and high-volume production use.

Everyday items we laser engrave

- Metal ID tags and asset plates

- Logos and branding on machined components

- Part numbers, batch codes, and serial numbers

- QR codes and barcodes for traceability

- Tooling and fixtures with custom identifiers

- Safety messages and instructional labels

- Covers, housings, and flat or curved faceplates

Our equipment and capabilities

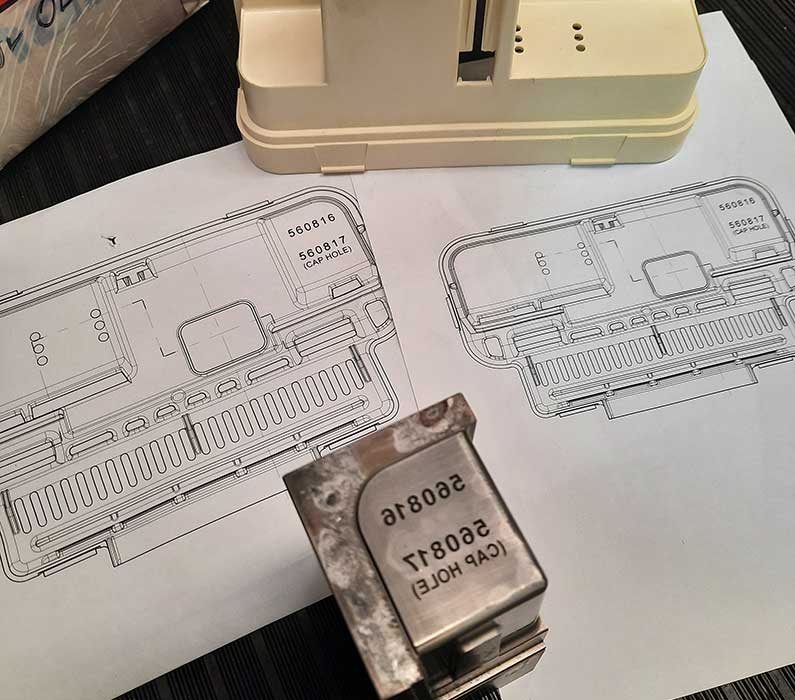

Hawk Tooling uses a 50-watt fibre optic laser engraver explicitly designed for marking metals with clarity and consistency. This system allows us to produce high-contrast, detailed markings on various parts and surfaces, all with repeatable precision.

We can mark individual items, batches of components, or ongoing production parts. Everything is done in-house at our Adelaide workshop, ensuring quality control and quick response for urgent or time-sensitive jobs.

Key capabilities include

- High-resolution marking of text, logos, graphics, and data codes

- Engraving depth control for surface etching or deeper cuts

- Clean results with minimal surface disturbance

- Work area of up to 300mm x 300mm

- Fast setup and turnaround for one-off or repeat jobs

Laser etching and engraving for Adelaide industries

Our laser marking services are used by businesses across Adelaide’s manufacturing, engineering and electronics sectors. You may need to track parts on the production floor, brand your components, or meet compliance requirements for traceability; we provide a fast, local solution.

Our services areas across Adelaide’s industrial zones

From our workshop in Lonsdale, we serve clients in Lonsdale, Edwardstown, Plympton, and Elizabeth South and work with clients across high-density industrial zones such as Port Adelaide, Salisbury, Wingfield, Pooraka, Beverly, Mawson Lakes, Mile End, Gepps Cross, Richmond and Tonsley. We also support regional South Australian businesses that need a reliable partner for high-precision metal marking.

Applications range from one-off ID tags to production marking on tooling, fixtures, and finished parts. If you need clean, durable engraving on metal delivered quickly and without complications, we’re here to help.

Why choose Hawk Tooling for laser engraving in Adelaide

With decades of experience in precision manufacturing and tooling, we understand how essential markings are to be clear, consistent and built to last. Our laser engraving service is designed for industrial environments where quality matters and deadlines are real.

What makes us a trusted partner

50W fibre optic laser system for crisp, permanent metal markings

35+ years of experience in engineering, machining, and tooling

Local service in Adelaide for fast response and minimal lead time

In-house control from setup to final inspection and no outsourcing

In-house quality control using metrology-grade equipment in a controlled environment

Personal service and advice from an expert who understands your job

Frequently asked questions about our laser etching and engraving services

display none

What’s the difference between laser etching and engraving?

Laser etching creates a shallow surface mark, while engraving removes more material for a deeper, longer-lasting result. We assess your part and application to recommend the most suitable option.

What materials can your laser engrave?

We specialise in marking metals, including stainless steel, tool steel, aluminium, brass, and copper. We focus on metal-only marking at this stage, but we’re happy to discuss material compatibility if you’re unsure.

What is the maximum size part you can engrave?

Our laser engraver accommodates parts up to approximately 300mm x 300mm. This is ideal for tags, plates, housings and small to medium-sized components.

What types of markings can you do?

We can engrave logos, serial numbers, part IDs, barcodes, QR codes, material specs, and safety information. Vector graphics and fine text are also possible with excellent clarity.

Will the marking wear off over time?

No. Laser engraving is permanent and resistant to wear, chemicals and abrasion making it suitable for industrial and outdoor environments. Etched marks are lighter but still durable.

Can you do one-off jobs, or only production runs?

We do both. Whether you need a single engraved tag or consistent markings across a full batch of parts, we can handle it in-house with quick turnaround times.

How fast can you complete a job?

Turnaround times vary depending on the job size and complexity, but we often complete small jobs within a few days. For urgent requirements, just let us know. We’ll do our best to accommodate.

Request a laser engraving quote today

Do you need part numbers, tags, or logos engraved on metal components? We deliver high-quality, permanent results with fast turnaround and expert service all from our workshop in Adelaide.

If it’s a one-off item or a batch of production parts, Hawk Tooling provides laser etching and engraving services you can count on.

Contact us today

- Discuss your part or material

- Send a file or example for review

- Request a fast, competitive quote