Laser welding Adelaide

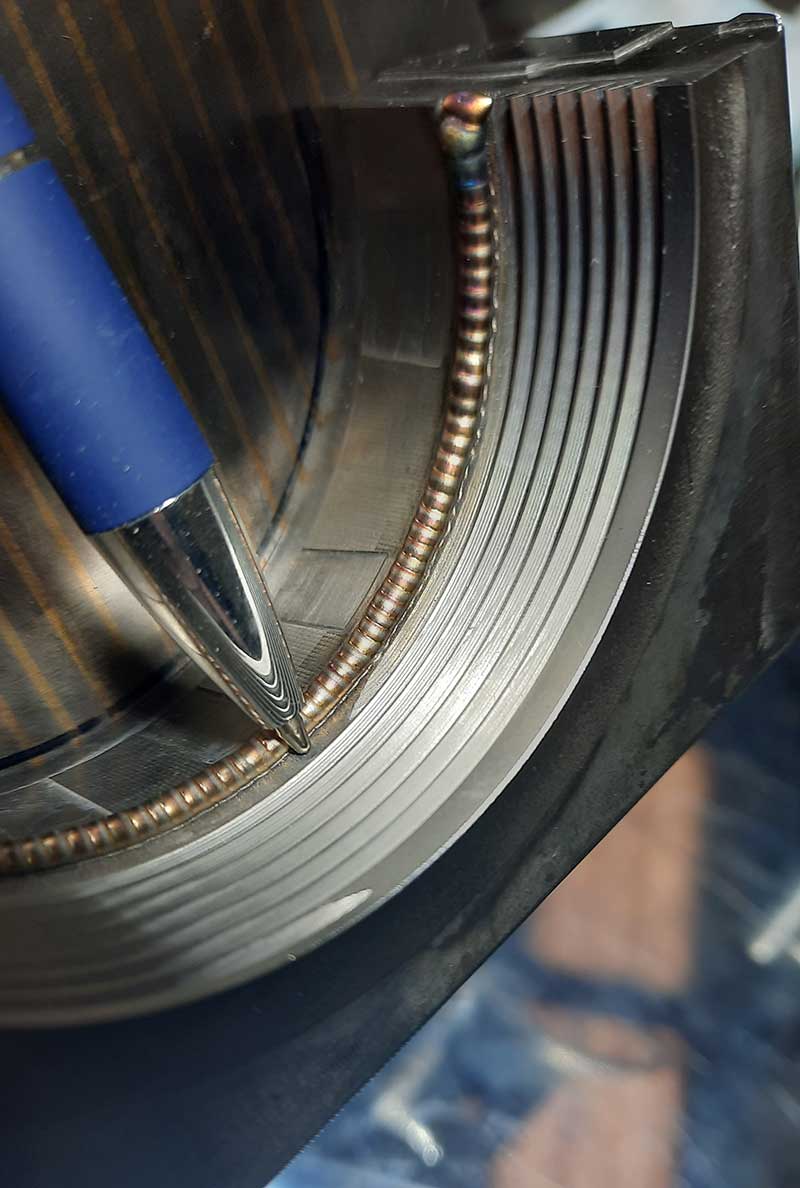

Precision laser welding for repair and restoration of molds, components, and tooling

Laser welding services

Hawk Tooling’s customers typically use our laser welding services to repair, rebuild or modify precision-engineered parts that demand high strength and minimal heat distortion. It’s the preferred method for restoring fine features in hardened steels, salvaging machined components with damaged or broken features, and joining delicate or complex parts where conventional welding methods isn’t suitable.

Hawk Tooling laser welding services

From injection molds to small mechanical parts, we help manufacturers restore performance, part quality and minimise downtime with fast, precise repairs.

- Rebuild worn or damaged cavity edges, shut-off faces, and mold features

- Restore tool faces or lifters while maintaining or correcting critical sizes

- Salvage CNC machining errors in high-value components

- Join sensitive parts where accuracy and low heat input are essential

- Extend the life of precision tooling and avoid complete replacement

Advantages of fibre optic laser welding

Laser welding offers several advantages over conventional welding, especially when working with high-value or precision-critical parts. Our 2KW fibre optic system allows for fine control, clean results, and minimal disruption to the base material. Our capabilities are especially valuable for mold shops, toolmakers and production teams who need dependable repair work without long delays or quality risks.

Common applications include

Minimal heat-affected zone (HAZ)

Reduces the risk of warping, distortion, or material weakening

High accuracy and control

Ideal for small features, intricate geometries, and tight tolerances

Cleaner welds

Produces neat joins with little or no post-weld grinding or finishing

Ability to Weld Hardened and heat treated steels

Suitable for tooling, molds, and hardened components without compromising hardness

Repeatable and consistent

CNC control ensures every weld is precise and repeatable, even on complex jobs

Reduces downtime

Fast, local repair option compared to complete part replacement or outsourcing

Typical components and tooling we laser weld

Our laser welding services are used across a wide range of tooling and part types, especially when precision and surface integrity are critical. We work with hardened steel, tool steels, and other engineering-grade materials that are used in industrial and manufacturing settings. Laser welding is often the most efficient and cost-effective repair option if a part is difficult to replace, sensitive to heat or too valuable to scrap.

Common applications include

- Injection mold cavities, shut-offs, gates and lifters

- Press tooling and die components

- Fine features on complex jigs or fixtures

- Machined parts requiring surface repair or dimensional adjustment

- PCB housings and electronic enclosures

- Custom or one-off precision parts in small to medium sizes

Our laser welding equipment and process

Hawk Tooling uses a 2KW fibre optic 4-axis CNC laser welding system to achieve consistently precise results on small to medium parts. This setup allows us to weld detailed areas, fine features, and complex geometries with exceptional control.

Key specifications and capabilities

We can work from customer-supplied CAD files, inspect physical parts, and advise on repair options. Every weld is performed with careful alignment and verified using precision metrology equipment to ensure quality and performance.

- 2KW fibre optic laser for high-strength, low-distortion welds

- 4-axis CNC control for precise positioning and repeatable accuracy

- Maximum part size: 600mm x 400mm

- Maximum weight up to 400kg

- Material compatibility for hardened steel, tool steel, stainless steel and more

Repair instead of replacing to reduce cost and downtime

Laser welding offers an innovative, cost-effective alternative to replacing damaged parts or tooling. In many cases, a worn or mismatched component can be restored to working condition in a fraction of the time and cost required to remake it from scratch.

Why do manufacturers choose repair over replacement

Repairing instead of replacing is especially useful for manufacturers on tight production schedules or dealing with obsolete or hard-to-source components.

Lower cost

Avoid the expense of full re-manufacture or replacement

Maintain fit and tolerances

Weld only where needed, keeping surrounding features intact to help minimise the amount of repair and rework.

Faster turnaround

Repairs are often completed locally and quickly, reducing production delays

Reduce waste

A more sustainable solution compared to starting over with raw materials.

Preserve high-value parts

Restore mechanical/physical function without scrapping expensive parts or tooling

Precision laser welding for Adelaide manufacturers and industries

Manufacturers, toolmakers, and engineers in Adelaide and across South Australia trust our laser welding services. We work closely with businesses that need high-precision part welding, repairs and restoration of tooling and components without compromising performance or production schedules.

Our laser welding services commonly support

Based in Lonsdale, south of Adelaide, we serve clients across the Adelaide metropolitan industrial areas, regional South Australia, and also support national businesses when specialist welding capabilities are required.

- Toolmakers and injection mold shops needing precise rework or cavity repair

- Plastic product manufacturers with high-volume production tooling

- Electronics and PCB assembly teams requiring fine welding on sensitive housings

- Mining and industrial manufacturers with hard-wearing, high-value parts

- Maintenance and engineering teams needing fast, accurate local repair options

Why choose Hawk Tooling for laser welding in Adelaide

With decades of hands-on experience and advanced in-house capability, Hawk Tooling is a trusted partner for precision laser welding in Adelaide. We combine technical expertise with fast, responsive service helping local manufacturers, toolmakers, and engineers restore critical components without delay.

From high-volume to one-off jobs, we deliver laser welding services that meet the demands of modern manufacturing.

What sets us apart

Over 35 years of experience in tooling, manufacturing, and component repair

2KW fibre optic 4-axis CNC laser welding system for high accuracy and control

Deep understanding of mechanical functionality, various material types, and precision part tolerances

Fast, honest quoting and direct communication with the expert doing the job

Located in Lonsdale, serving all Adelaide’s industrial zones

Reliable outcomes; done right the first time

Frequently asked questions about our laser welding services

display none

What materials can be laser welded?

We commonly laser weld tool steels, hardened steels, stainless steels, aluminium (to some extent), and other engineering-grade alloys. Our system is ideal for precision work on hard-wearing or heat-sensitive materials that require controlled energy input and minimal distortion. We’ll advise on material compatibility as part of the quoting process.

What is the maximum part size and weight you can handle?

Our setup allows us to laser weld parts up to approximately 600mm x 400mm and 400kg in weight. It is ideal for small to medium-sized components, injection molds, tooling, and detailed assemblies. We will assess and offer alternative options if your part falls outside this range.

Can laser welding restore worn or damaged tooling?

Yes, this is one of our most common applications. We use laser welding to rebuild worn cavity edges, shut-off surfaces, lifters, gates, and other critical mold features. It’s a cost-effective way to extend tooling life, avoid complete replacement and maintain dimensional accuracy.

Is laser welding better than TIG or MIG welding?

For small, intricate, or high-precision jobs, laser welding is superior. It produces a minimal heat-affected zone (HAZ), delivers a cleaner weld and allows for tighter control. It’s especially beneficial when working with hardened materials or when surrounding features must remain untouched.

Do I need to supply a CAD file to get started?

No, although CAD files are helpful. We can work from physical parts, technical drawings, or even hand-marked damage if needed. If you don’t have digital files, we’ll inspect the component and advise on the most efficient repair approach.

How long does a laser welding job typically take?

Turnaround time depends on the complexity of the job. Simple repairs can often be completed within a few days, while more detailed or multi-surface work may take longer. We’ll always give you a clear time estimate when quoting.

Can you inspect the part after welding to ensure accuracy?

Yes. All work is checked using our metrology equipment, including Mitutoyo instruments, microscopes, and surface gauges in a climate-controlled inspection area. We ensure that all welded parts meet functional and dimensional requirements before return or delivery.

Get a laser welding quote or speak with an expert

Do you need to repair a worn tool, restore a precision component, or salvage a high-value part? Hawk Tooling provides expert laser welding with minimal heat distortion, ideal for small to medium components and production tooling.

We handle the work in-house using 4-axis CNC fibre laser technology, ensuring high accuracy, fast turnaround, and personal communication every step of the way.

Contact us today

- Discuss your part or tooling repair requirements

- Get advice on weldability, materials, or tolerances

- Request a fast, competitive quote for laser welding