Plastic injection molding and press tooling services in Adelaide

Small to medium toolmaking for molds, dies and production components

Plastic injection molding and press tooling services

Hawk Tooling’s tooling services are trusted by manufacturers, mold shops, and production teams who need reliable, high-performance tools that meet tight tolerances and stand up to real-world use. You may be starting from a concept, working from detailed drawings, or needing to rebuild an existing tool. We offer expert advice and practical support from design through to delivery.

We support a wide range of tooling needs

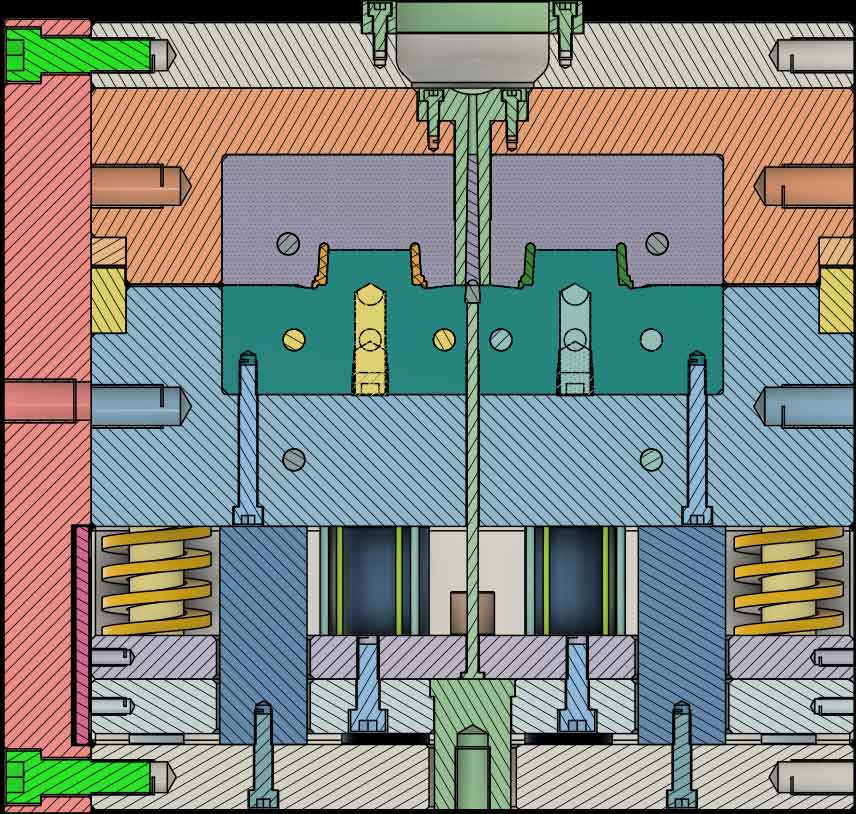

- Designing and building injection molds for plastic part production

- Manufacturing press tools and dies for forming metal components

- Modifying existing tools to improve part quality or production efficiency

- Repairing worn or damaged tooling to extend its service life

- Assisting with small to medium tool builds or modifications.

Tooling we design, build and support

We specialise in small to medium tooling solutions designed and built to suit production requirements, material demands, and operator workflow. Our experience covers both simple and complex tooling, always emphasising function, reliability and ease of maintenance.

We work with these areas

Injection molds

From open-and-shut designs to multi-slide, lifter, stripper plate, and hot runner systems

Press tools

For metal forming, blanking, punching, and trimming

Tooling inserts and components

Including cores, cavities, pins, part ejection, material insertion and external critical parts.

Fixtures and jigs

Used in machining, welding, setups and assembly

Tool rebuilds and reworks

Extending tool life with repairs, upgrades, modifications and insert replacement

Custom-built tools

For unique applications or parts with specific forming or dimensional needs

Our tooling capabilities and process

Hawk Tooling manages the entire tooling workflow in-house, from initial concept and CAD modelling through to machining, welding, assembly, and testing. It allows us to maintain control over quality, speed up turnaround times and respond quickly to changes or repairs.

Our capabilities

We handle tooling up to 1000kg and specialise in building, modifying, or repairing tools that others may consider too small or too complex. For every job, we focus on practicality, durability, and getting you back into production without unnecessary delays.

CAD design using Autodesk Fusion and AutoCAD

We design complete tooling packages or individual inserts, part ejection systems, and features with precision and clarity.

CNC machining

Key tool components are machined in-house using 4-axis milling and CNC turning to achieve tight tolerances.

Laser welding

Used to repair, rebuild, join parts or adjust fine features and critical tool surfaces with minimal heat distortion.

EDM and manual finishing

For detailed cavity forms, narrow ribs or slotting, and hard-to-machine geometries.

Tool fit-up and inspection

We assemble and review each tool to ensure proper alignment, function, and part ejection before deployment.

From concept to production how our tooling process works

If you’re building a new tool or modifying an existing one, our process is designed to ensure precision, performance, and a smooth path to production. We manage every stage in-house to reduce downtime, cost, and uncertainty.

Step 1

Review requirements or inspect the existing tool

We start by reviewing your part files, production needs, or the condition of your existing tooling. If you’re unsure where to begin, we can advise based on experience.

Step 2

CAD design and modelling

We create a detailed 3D model using Autodesk Fusion 360, including all tool components, inserts, and moving parts. You’ll receive the model for review and approval before we begin building.

Step 3

Machining and fabrication

Tooling components are machined mostly using CNC milling and turning, with the addition of grinding, EDM, polishing, and welding when specific requirements are called upon.

Step 4

Assembly and test

We fit up, lubricate and inspect all tool components, ensuring proper alignment, ejection, and tolerances before release. This may include water testing, dry running or part simulation.

Step 5

Support and servicing

After delivery, we can provide ongoing support, modification, or repair. Many clients return to us for tool servicing, tuning, upgrades, or urgent rebuilds.

Tooling design and manufacturing for Adelaide industries

Hawk Tooling works with manufacturers, mold shops, and engineering teams across Adelaide who rely on precise, durable, and production-ready tooling.

From our workshop in Lonsdale, we serve clients in Lonsdale, Edwardstown, Plympton, and Elizabeth South and work with clients across high-density industrial zones such as Port Adelaide, Salisbury, Wingfield, Pooraka, Beverly, Mawson Lakes, Mile End, Gepps Cross, Richmond and Tonsley. We also support regional South Australian businesses that need a reliable partner.

Our customers

We regularly work with production supervisors, toolroom managers, maintenance teams, and engineers who need fast, responsive service, especially when tools wear, fail or must be adjusted to keep production moving.

With decades of practical experience, we know how to design and build tools that integrate into your workflow and meet the realities of daily use.

Our tooling is used in a range of applications

- Plastic injection molding

- Metal forming and stamping

- Assembly fixtures and jigs

- Short-run and specialist production setups

Why choose Hawk Tooling for tooling design in Adelaide

We’re more than a regular machine shop. We are toolmakers with decades of experience designing, building and repairing tooling that performs under pressure. Our approach is hands-on, detailed and focused on getting you back into production with tools you can trust.

Here’s what sets us apart

35+ years of experience in toolmaking, manufacturing, management and design

Specialised in small to medium tooling ideal for most local production environments

In-house CAD design, CNC machining, and laser welding for complete control and fast turnaround

Flexible support for full builds, modifications, repairs, and reworks

Direct communication with the toolmaker doing the job; no layers, no guesswork

Trusted by Adelaide manufacturers for consistent quality and practical solutions

Frequently asked questions about our tooling services

display none

What types of tooling do you design and build?

We design and manufacture injection molds, press tools, die components, jigs, and fixtures. Our tooling supports both plastic part production and metal forming, and we also handle rebuilds and reworks of existing tools.

What is your tooling size capacity?

We specialise in small to medium-sized tooling, up to approximately 1000kg. This suits most production environments in Adelaide and is ideal for short-run, high-precision, or specialised tooling needs.

Can you repair or modify existing tools?

Yes. We regularly repair worn tooling or modify existing tools to extend service life, improve part quality, or insert changes in product requirements. Laser welding and CNC machining allow us to restore fine details with minimal disruption.

Can you build tooling from a sample or part, not just a drawing?

Absolutely. We can reverse-engineer tooling based on a sample part or work from sketches and basic measurements. Our CAD tools allow us to create a production-ready design for your reference.

Do you offer complete CAD design with the tooling build?

Yes. Every tool we manufacture is first modelled using Autodesk Fusion or AutoCAD. This allows you to review and approve the design before machining begins and ensures accuracy and alignment with production goals.

How long does it take to manufacture a tool?

Lead times depend on the complexity and size of the tool. Simple open-and-shut molds may take a few weeks; more complex tooling will take longer. We’ll always provide a clear estimate at the quoting stage.

Do you provide support after the tool is delivered?

Yes. We stand by our work and offer ongoing servicing, rework, and troubleshooting if needed. Many clients return to us for regular maintenance, adjustments, or upgrades to existing tooling.

Request a tooling quote or project consultation

Do you need to build, repair, or modify injection molds, press tools or production tooling? Hawk Tooling provides expert tooling design and manufacturing in Adelaide with fast turnaround and daily performance in mind.

From concept to completion or even urgent tool rework we deliver practical solutions that keep your production on track.

Contact us today

- Discuss your tooling requirements or part sample

- Review an existing tool for repair or modification

- Get a fast, competitive quote from an experienced toolmaker